|

by

|

|

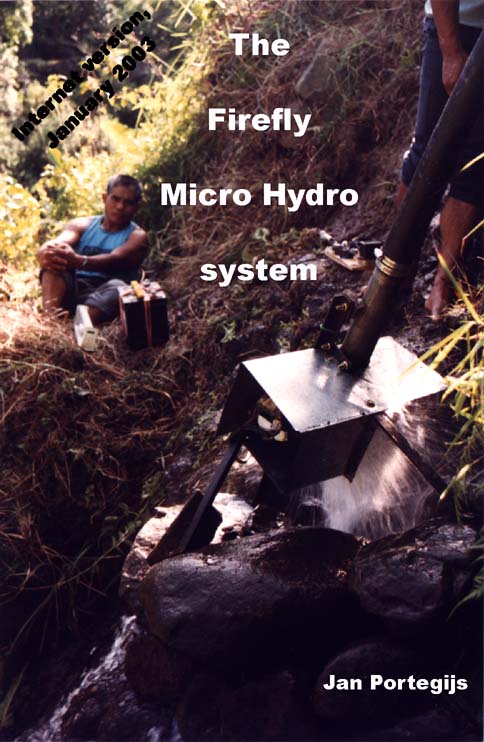

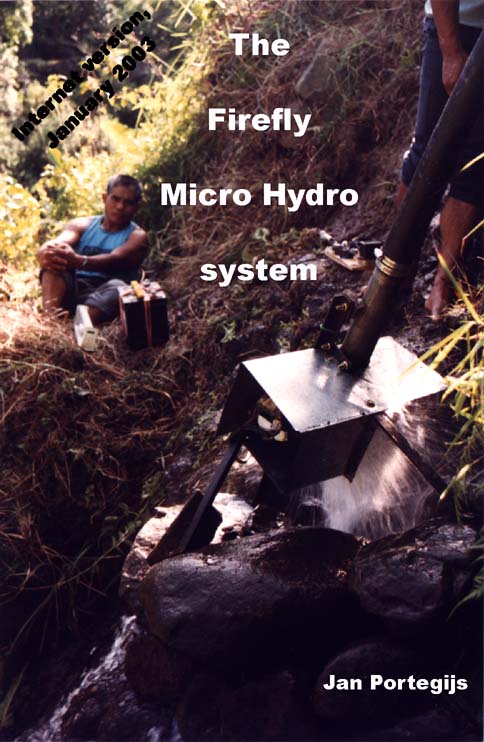

| Picture: The first time the prototype

charger was running at the site in pilot village Cambulo,

Banaue, Ifugao prov., Philippines. |

| 1.1 |

A real firefly.

It's an impressive sight to see thousands of them

twinkling in a tree on a moonless night. |

| 1.2 |

High school students

testing the charger they have built. The man

listening so attentively is their physics teacher. With

thanks to the Gouda firebrigade for lending them a pump. |

| 2.1 |

Typical layout of an

installed firefly charger, schematic drawing. |

| 2.2 |

The first prototype in

the workshop where it was built. There was no drill,

holes in the frame had to be cut using an electric arc

welding set at full blast. Covers are not fitted yet. |

| 2.3 |

The Cambulo coop store. |

| 2.4 |

Ben Nanglihan is

preparing a battery for use. Connections are made and

it must be filled with acid: A tricky job. He'd better

wear safety glasses and have his son playing somewhere

else. |

| 3.1 |

Cambulo, the pilot

village of PRRM's Micro Hydro project. To irrigate

the rice terraces, there are small irrigation canals and

one of them was used for the charger. |

| 3.2 |

Rosita Bentican signs a

loan agreement. Materials for the home system were

sold on installment basis. Rosita is a teacher so she

needs good light at night and earns enough to afford it. |

| 3.3 |

The trail to Cambulo: A

12 km hike to the nearest road. It is unlikely that

Cambulo will be connected to the national grid in the

foreseeable future. |

| 4.1 |

The standard

charger: Not a big thing. The shield around the

runner is not fitted yet. |

| 4.2 |

The charger seen

from below. The amount of water coming through it is

quite impressive. |

| 4.3 |

Characteristics of

standard charger. |

| 4.4 |

Making the blades. |

| 4.5 |

Bending blades with a

makeshift press. |

| 4.6 |

Making side disks. |

| 4.7 |

Using modified jigsaw

sawblades for cutting slots in side disks.<<

Nog noemen: Het kan ook met hacksaw sawblades that are

grinded off at the side opposite of the teeth.>> |

| 4.8 |

A modified vernier

calliper for marking circles on steel. |

| 4.9 |

A jigsaw machine

adapted for cutting side disks in series. |

| 4.10 |

A modified jigsaw

sawblade for use with a jigsaw machine. |

| 4.11 |

Soldering a runner. |

| 4.12 |

The seal and the

way to fix the runner on the shaft. |

| 4.13 |

The separation

sheet. |

| 4.14 |

The other parts of

the seal. |

| 4.15 |

Sides of the nozzle. |

| 4.16 |

Two possible shapes

for a blocking timber. |

| 4.17 |

Nozzle sides

assembled. |

| 4.18 |

The extension pipe. |

| 4.19 |

A flanged connection,

please note: Not on scale 1:1. |

| 4.20 |

Parts of the frame. |

| 4.21 |

The frame

assembled. |

| 4.22 |

A square made out

of one piece. |

| 4.23 |

The frame with the

nozzle welded on. |

| 4.24 |

Covers and shield. |

| 4.25 |

Electrical

circuit of the charger. |

| 4.26 |

A scale for the

indicator. |

| 4.27 |

Relation between

charging current, voltage and state of charge (copied

from VAN DER MEER, 1990). |

| 4.28 |

The charging

process as a function of time. |

| 4.29 |

A complete

switchboard. |

| 4.30 |

The back side of

the switchboard front panel, with all components and

wiring fitted. |

| 4.31 |

Modifying a

mechanical, 6-wire Japanese voltage regulator. |

| 4.32 |

An expensive,

permanent forebay tank. |

| 5.1 |

Ruud Portegijs

helps Leon Bentican wiring up his house. |

| 5.2a |

Stabilised voltage

supply for 6 V output. For 9 V output, use device `7809'

instead of `7806'. |

| 5.2b |

Stabilised voltage

supply for 4.5 V or 3 V. |

| 5.2c |

Charging NiCd

batteries with a series resistor to achieve the right

current. |

| 5.2d |

Constant current

device for recharging 1 up to 6 NiCd batteries in one go. |

| 5.2e |

Circuit for

recharging small, 6 V, maintenance-free lead-acid

batteries from the main battery. The LM 317 must be

mounted on a piece of aluminum for cooling. The part of

the circuit with transistor and LED's can be omitted, it

only serves to show whether the charger is functioning

and whether the battery is charged already. |

| 5.3 |

Electrical

circuit of home system. |

| 5.4 |

Component layout

and copper pattern of the Printed Circuit Board for the

indicator. |

| 5.5a |

Twelve copies of

the PCB copper pattern (in mirror image) fitted on

standard size PCB board.

Note: For correct dimensions, print this figure at 300

DPI (Dots Per Inch). |

| 5.5b |

Alternative: Eight copies

of PCB design with current shunt.

Note: For correct dimensions, print this figure at 300

DPI (Dots Per Inch). |

| 5.6 |

An indicator with

copper wire switch. This one has an older version of

the PCB: A lying trimmer is used and the placing of some

components is different. The wound-up wire underneath is

the current shunt. |

| 5.7 |

Cross section

through copper wire switch. |

| 5.8 |

A plexiglass

cover. |

| 5.9 |

Relation between

state of charge and open circuit voltage. Treshold

voltages and reference voltages of the indicator are also

drawn in. |

- Some drawings might be wider than your browser

window and then a horizontal scrollbar will appear. Such drawings are easier to view

when your browser window is as wide as possible. Maybe select a larger screen size in

your computer system settings.

A wide browser window makes that text is printed with

very long lines. For reading the text only, a narrower

window might be more comfortable. Or you might select a larger font size

("Text size" in "view" menu) to make text better readable.

- For viewing pictures: Adjust `brightness'

and `contrast' of your monitor such that the full color range is

distinguishable ("dark grey" should look different than "black").

Text becomes easier to read when brightness is

adjusted very low and contrast so high that the white

background is just light enough (then "dark grey" and "black" look the same).

- For printing the text: Try out first which font size setting (see above) gives

well readable text without using too much paper.

- If you use the "print" option of your browser, most likely drawings will not be

printed at the right scale. For printing drawings to scale, you need a copy of the image

file at your own computer. If you downloaded and unpacked the manual, you can

just select the right image file: Its file name starts with its figure number.

If you are viewing it on-line: Right-click on the drawing you want

and choose option "Save picture as" to download it.

Open the image file with an imaging or photo processing

programme and print it at 150 DPI (Dots Per Inch). If it

is not possible to specify a DPI in the `print' option,

look for an option like `adjust image size', and then set

it to 150 DPI while maintaining file size.

Please note: Figure 5.5.a and figure 5.5b must be printed

at 300 DPI to get them at the right size.

- There is no index. For searching on keywords in the downloaded version,

you might use the windows "find" tool to get a list of files where a

keyword is mentioned. Below, the procedure for Windows NT is given, for

other Windows versions, it might be a bit different:

- Press "Start" button

- Select "Find"

- Select "Files or folders". The "find" window pops up

- In tab-sheet "Name & Location", field "look in:", browse to the

subdirectory where the un-packed *.html files of this manual are

- In tab-sheet "Advanced", field "Of type", select the type

corresponding to *.html files, e.g. "Netscape Hypertext Document"

- In this tabsheed, field "Containing text", fill in the keyword you

want to search for

- Press "Find Now"

- If the keyword is found in one of the files: Open this file with your

browser and use its "find" function (under "Edit", or use <Ctrl>+"f"

or <Alt>+"f")

For searching in the online version, you might use the "Search" function

of mr. Klunne's main micro hydropower page

and open only pages in subdir ".../portegijs/firefly_bm"

This book is meant as a manual for building a

firefly Micro Hydro system and setting up a firefly demonstration

project. It is still a draft version. The chapters on technical

issues are reasonably well worked-out by now. The introduction

chapter, the ones on the firefly system in general and on local

conditions have not been written with that much care. The last

two chapters and many of the annexes have not been written yet.

In an attempt to keep copying and postage costs within budget,

the annexes that are available, are not printed in this book.

These can be requested with me. Most of them deal with the

considerations behind the technical design and are not relevant

for people who just want to build a system. Background

information that might be relevant to some readers, has been

printed in boxes dispersed through the text. To keep lay-out work

simple, these boxes are not printed as separate blocks of text,

but only printed in italics and numbered.

For people who have got the previous draft

version (of July 1994), an overview of the major changes might be

interesting:

- Since then, I have built two firefly

chargers and have tested one of them. My experiences in

this has lead to many minor changes in charger design and

in the way it could be produced. There are two important

changes:

- Nozzle design has been changed,

see box 4.7 on page 4-12.

- An `elco' capacitor has been

included in the switchboard circuit to protect

against voltage spikes, see box. 4.15 on page 4-62.

- The design and calibration of the charge

indicator has been changed. It used to be based on a

relation between open circuit voltage and state of charge

of the battery obtained from SOLAR ENERGY COURSEBOOK but

clearly these data were unreliable, leading to state of

charge being seriously underestimated. Now it is based on

a formula that is widely used in Holland and appears much

more realistic.

- People who probably had as little

technical experience as you, dear reader, have

succesfully test-built major parts of the firefly system

(see par. 1.2). So having no technical experience can not

be used as an excuse any longer for claiming not to be

able to build a firefly system.

- Chapter 2 and 3 have been written, I hope

you will find them interesting.

- Pictures have been included.

To improve this draft version further and turn

it into a useable book, I would very much appreciate reactions

from readers. So please take time to write me your comments.

Another request to readers: I would like to

receive data on firefly systems that have been built and

installed. Aspects that are important to me are:

- Names, addresses, location on the map: Who

built it, what agency is working on introducing the

firefly.

- General conditions in the area (see

chapter 3).

- Conditions at the site: Head, length,

diameter and material of penstock pipe, was a blocking

timber installed and if yes: What width.

- The user group, number of users, the way

it was set up, arrangements within the user group, the

way potential users look upon the firefly. Information on

how the firefly was introduced in your area could be very

interesting for people in other areas as well.

- Technical design: What charger design was

used (of this version or of the previous draft version)

and any deviations from this design. Was it built very

accurately or rather rough. And on the home system: What

type of battery, what type of lamps, any minor uses etc.

- Something on the economics.

- Pictures, of the area, the charger site,

the charger and of users.

- Experiences until now, plans.

- Remarks, recommendations to other people

who consider trying to introduce the firefly in their

area.

- And last but not least: Problems, things

that proved more difficult than expected, errors that

were made but corrected later.

I hope to use these information to improve the paragraphs

on troubleshooting. My own ideas on what problems could

crop up probably are less relevant because I know too

well how the system should work. People trying to get

things working might come across completely other

problems and these should be included in those paragraphs.

I know that answering these questions in detail

would take too much time for most readers. So please write down

some basic information rather than to postpone writing until you

find time to answer them all. Of course I am willing to give

advice to readers who write me about problems they could not

solve themselves.

Finally, I would like to thank some of the

people who have contributed to my work on the firefly system.

First there is engr. Simon Taylor, my successor at PRRM-Ifugao.

His letters gave many hints on aspects of the design that weren't

worked out properly yet and kept me in touch with what happened

in the Cambulo project. Two frends gave valuable comments on the

technical design: Willem Steyvers van Orsselen, a marine

engineer, and Siem Broersen, an electronic engineer. Then there

were the people who took the time to test-built some major parts:

Catharien Ternisscha van Scheltinga and Jacobijn van Etten who

built the charge indicator, and Fleur de Bruin, Gonnie van Dijk,

Joost Kaptein, Eric Schulte, Maurice Simons, Saskia Stolwijk,

Dominique van Unen en Josefien Versteeg, the `Gouda Group' high

school students who built a charger and Theo van der Geest, their

physics teacher. Fa. J. Dignum and sons let me to use their

tractor and irrigation pump for testing a charger. Finally I

would like to thank the people from `Casa de Pauw' for allowing

me to use their workshop and computers, with special thanks to

Wim van der Hoek, who kept me going with many cups of coffee,

funny remarks and inspiring comments.

There are many more people who have contributed

to this project, too many to mention them all here. I won't

forget them...

Jan Portegijs, 9 September 1995

Copyright: Jan Portegijs, 1995.

Copying minor parts of this book with literature reference is

allowed without prior authorisation. Copying major parts or the

whole is allowed if the copies are meant for private use only.

A lot has happened since I finished the draft

version in 1995: I went back to the Philippines to support two

Philippine organisations with their efforts to introduce the

firefly. This trip was paid by Dutch ODA dept. and I started my

own little consultancy enterprise to qualify for that funding. My

frend Siem Broersen and I developed the 'Humming bird' Electronic

Load Controller / Induction Generator Controller and I wrote a

building manual on that. Meanwhile, I got to know a lovely,

pretty woman. We decided to try our luck and by now, we have two

nice kids that need our care. Since this first ODA job, I hardly

earned any money with my consultancy work so did odd jobs.

Eventually, I ended up in computer work, making industrial

automation software. Now I am working for a large company that

produces high-tech machines for the computer chips industry.

One thing did not happen: I never wrote the

missing chapters and annexes for this manual... And I don't think

I ever will so quite likely, this manual will forever remain an

incomplete, draft version. There is one obvious reason: I don't

want to spend all of my spare time for the next year writing them.

But there are some other reasons too:

- I am less optimistic about chances that

the firefly will 'break through'. From a technical point

of view, the batteries are a weak point: Life span is

poor when they are discharged too deeply and chances are

that the case gets damaged when they are carried around

so often.

Solar energy has similar battery problems and still is

much more expensive, but it is more convenient: No

carrying of batteries and no troubles about sharing a

charger with other users. And above all: There are

funding agencies, solar cell suppliers, traders, local

technicians who all support it and earn a living from it.

So I guess that solar energy will win the race even in

areas where suitable water sources are available. Maybe

the firefly is too cheap....

- I lack the experience about using the

firefly in practice and setting up a firefly introduction

project. I think these are the most interesting parts,

but I can only write down some generalities and common

sense about them.

I could write the technical annexes, but I doubt whether

that would make much of a difference. Part of it would be

rewriting pieces of technical school books. I guess that

most people who want to build a firefly system, will have

enough technical knowlegde themselves or can find such

information themselves. Then there are specialistic

issues about details of the firefly system. These are

relevant for readers who would like to adapt the firefly

to their own needs. Until now, I did not receive concrete

questions about these from readers so I guess there is

not a great need for such information either.

- The best way to exchange experiences

between people and organisations using the firefly,

nowadays is via internet.

So this is what I want to do: Build and

maintain a web site on firefly projects worldwide, with reports,

photo's, contact addresses, links to sites that people have made

themselves, see:

http//www.microhydropower.net/mhp_group/portegijs/firefly_exp/ffexp_index.html

If you have something to show or tell, mail it

to me and I will see whether it fits in.

Apart from several mistakes that were corrected

and a small number of additions, this downloadable version is

identical to the printed version of September 1995.

Jan Portegijs,

9 February 2003

This section is meant for people who have the

paper version and would like to update it. In this internet

version, these additions and corrections have of course been made

already.

Insert at page 4-10 under figure 4.7:

Hacksaw sawblades can be used also.

In charger building workshops in the Philippines, people used hacksaw sawblades of

which about half of the height of the blade was grinded away and probably even more at the

side where it touches the outer edge of the slot. With such sawblades fitted in a normal

hacksaw, they could cut the slots quite fast. However, the side disks I have seen, had slots

with radiuses quite a bit larger than the design value of 14.2 mm and consequently, blades

will be less strong. Also the width at the teeth is only 1.0 mm instead of 1.4 mm for

jigsaw sawblades. One could try to widen the slot by cutting away material from one of the

sides, but this means extra work and a less smooth result. Normally, only 1.0 mm thick

blades will fit in (instead of 1.25 mm) and this makes the blades even weaker. If you are

interested, see the picture "Joel Cubit cutting a side disk" in:

http://www.microhydropower.net/mhp_group/portegijs/firefly_exp/ANEX_s.html

Insert at page 4-27 between

"Both versions have been tested and worked fine up to free

running speed at respectively 12 and 15 m head"

and

"With a pulley that consists of two halves..."

Anti-splashing ring for seal for pulley in one piece

With the seal type for a pulley in one piece, there was still a

leakage problem: Some water comes through and gathers at the

bottom of the alternator compartment. It does not pose a real

danger as it comes through as a liquid and not as a fine mist of

water droplets that can be sucked into the alternator: One could

even drill a hole through the separation sheet at its lowest

point to get rid of it.

Probably the water can come through because there is a jet of

water leaking away between the runner and the nozzle. This jet

hits the separation sheet just outside of the pulley and

apparently, some water is forced inwards through the narrow gap

between the pulley and this sheet. A solution would be to fit an

anti-splashing ring of 0.5 mm galvanised iron sheet, inner

diameter = 6 mm, outer diameter = 100 mm between the runner and

the pulley (see fig. 4.12). This ring should prevent the water

jet from splashing against the separation sheet at high speed. I

haven’t tested this solution yet, please let me know whether

it works.

Insert on page 4-31 below figure 4.16:

Adjustable nozzle.

Instead of fitting a suitably sized blocking timber inside the

nozzle, one could also adapt nozzle design such that the flow

through it, can be adjusted. This can be done by making part of

the inward side hinge towards the bent side. See:

http://www.microhydropower.net/mhp_group/portegijs/firefly_exp/Tech_issues.html#adjustable_nozzle"

for a design. Such an adjustable nozzle comes in handy for:

- A demonstration charger that will be installed temporarily at sites with different heads.

- When available flow is less than the charger needs. Then one could adjust the nozzle such that it takes just a bit less flow than the canal provides so that the penstock remains full of water and the charger produces some power. Without reducing the flow, air would enter the penstock pipe, the charger would operate at a reduced head and a reduced flow and power output would be minimal.

Insert on page 4-44 at the end of par. 4.9.1:

Electronic switchboard.

There is also a design for a fully electronic switchboard, see

http://www.microhydropower.net/mhp_group/portegijs/firefly_exp/Tech_issues.html#elect_switchb

It is more user-frendly and it can charge two batteries in one go. But it requires quite some electronics experience to build.

Insert on page 4-62 between:

"When the switchboard is ........... and might make short

circuit etc.:

and

"Box 4.15: Voltage spikes"

Mechanical regulator might work inaccurately

Mechanical regulators might overcharge batteries batteries when

used in a firefly switchboard. Once the battery becomes charged

and voltage surpasses 14.7 V, the regulator does not reduce field

current properly, but continues to provide full field current.

Consequenty the battery is charged further and battery voltage

rises to well over 15 V. Probably, this is caused by the contacts

of the voltage regulator relais sticking together after having

sparked a little. In a car, this problem would not occur because:

- With the motor running, the voltage regulator will vibrate.

This is enough to make the contacts come loose

- The alternator can produce a much higher charging current. Then

battery voltage with a fully charged battery might be well over

17 V, so the voltage regulator coil will pull the contacts loose

more strongly.

The extra force needed to pull loose sticking contacts will

differ all the time so this problem can not be solved by to

readjusting the regulator to a lower voltage: Then on other

occasions, it won't charge batteries well enough. It makes sense

to check whether the spark extinghuishing diode is functioning

properly. If this doesn't help: Look for an electronic regulator.

Change in table 5.2: Parts list for the charge indicator

On page 5-13, the number of red LED's should be 2 pc (instead of

3). The number of green LED's should be 5 pc (instead of 4).

Size of standard PCB board is 160 mm (instead of 150).

On page 5.16, replace "150" by "160" in the

following paragraph:

- Are the dimensions still correct. The cadre around the 12

copies should measure 160 <instead of 150> x 100 mm. If on

the copy, the length deviates more than 5 mm from this 160

<instead of 150> mm, the transparant is unusable because

the pins of the LM 3914 chip would fit badly in the holes of

<remove "on"> such a PCB.

At page 5-17 add "the diode" in paragraph:

- The square ones, for the copper wire switch, the diode and for

the connections to the outside. These can best be drilled with 1

mm, so that ...

On page 5-16, add new figure

Fig. 5.5b: Alternative: Eight copies of PCB design with current shunt.

Click on the link to find this figure, then right-click on the figure and select "save picture as" to copy it to your local computer and print this copy at 300 DPI (Dots Per Inch) using an imaging or photo processing programme.

Insert on page 5-20 between:

"....the `B-' and `L-connection must be short-circuited with

a piece of wire."

and:

"As stated in the parts list, the current shunt consists......"

Instead of making a current shunt from copper wire, one could

also use the PCB design of fig. 5.5b with an on-board

current shunt. With this PCB design, there is a copper strip

between `B-' and `L-' that has such a length and width that its

resistance is ca. 0.02 Ohm. Of course also thickness of this copper

strip plays a role, so it can only be used with PCB material with

the usual 0.035 mm copper layer. When in doubt: Check resistance

afterwards by having a stable DC current going through it (e.g.

from a lamp connected to a battery) and measuring voltage drop

over the shunt with a digital tester on mV DC range.

Insert new text in parts list at page 5-12 in column 1 under "Current

shunt, 0.02 Ohm"

(or use PCB design with on-board current shunt, see fig. 5.5b)

next (= chapter 1)

More information on hydropower at the

microhydro webportal