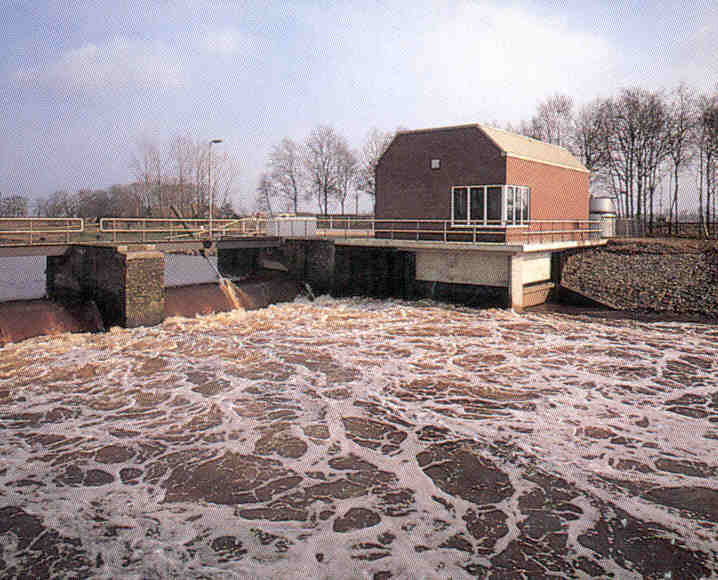

In 1987 in the river Vecht, next to the

weir 'De Haandrik' in the municipality Gramsbergen, the power company

Ijsselmij built a hydropower turbine with an electric power capacity of

100 kW. The project consists of a hydropower turbine and the necessary

construction work. The investment amounted to about 1.5 million Dutch

guilders (approximately € 700,000). Expectations are that the turbine

will generate 530,000 kilowatt-hours of electricity per year; which will

be supplied to the public electricity network. Subsidies from the Ministry

for Housing, Regional Development and the Environment (non profit) and

the Dutch Power Development Company (demonstration project) made the realisation

of the project possible.

In 1987 in the river Vecht, next to the

weir 'De Haandrik' in the municipality Gramsbergen, the power company

Ijsselmij built a hydropower turbine with an electric power capacity of

100 kW. The project consists of a hydropower turbine and the necessary

construction work. The investment amounted to about 1.5 million Dutch

guilders (approximately € 700,000). Expectations are that the turbine

will generate 530,000 kilowatt-hours of electricity per year; which will

be supplied to the public electricity network. Subsidies from the Ministry

for Housing, Regional Development and the Environment (non profit) and

the Dutch Power Development Company (demonstration project) made the realisation

of the project possible.

Moreover; the kind co-operation of the

Department of Public Works and the Department of Domains must not go unrecorded.

As part of the co-operation with developing countries, the Dutch Government

also aims at developing products which in the third world can lead to local

economic development. This starting-point prevailed upon developing the

water turbine adopted in this project.

As a power company, the ljsselmij wishes

to contribute to the afore-mentioned aim by investing in a model project.

Upon planning the project, Ijsselmij handled the principle that the project

would be executed when the costs of the generated power could be compared

with those of generation in conventional power stations. A Government

subsidy is therefore required.

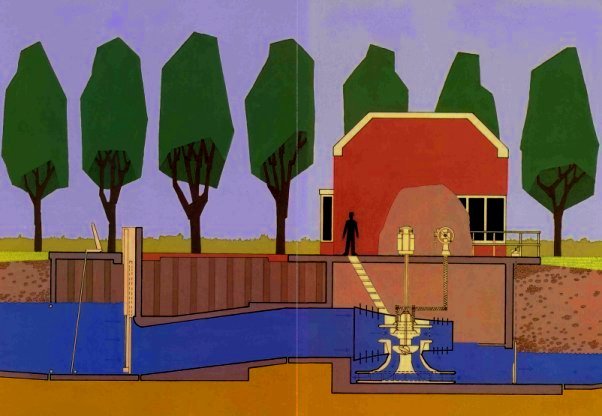

In the concession area of Ijsselmij, the

weir 'De Haandrik' is, in view of the water flow, the drop height and the

necessary constructional facilities, the best possible location for a water

turbine. In consultation with the Department of Public Works it was decided

to realise the turbine to the left of the weir; looking downstream. The

unit is installed on a pile-driven concrete foundation. The turbine is

developed and supplied by the Machine Factory Jansen Venneboer b.v. in

Wijhe, and equiped with a four-bladed rotor of which the blades are adjustable.

The advantage of this adjustability is that the power of the turbine can

be optimised to the local conditions as the water quantity and the drop

height difference in each situation.

By means of a gearbox, the low rotor speed

of 150 revolutions per minute is increased to the required operating speed

of the synchronous generator of 1500 revolutions per minute. An automatic

control valve enables the power of the turbine to be controlled. This

valve is situated in front of the guide blades and replaces the complicated

conventional system of adjustment of the guide blades. The function of

the valve is the adjustment of the generated power with preservation of

the highest possible output. The building height of the turbine could be

limited as the diffusor (outlet opening) is also the base of the turbine.

This is very important with a limited drop height. In view of the applicability

of the turbine in developing countries, special attention was given to

the reliability and the low sensitivity to disturbances, together with

a favourable price/performance ratio.

The maximum drop height is about 2 meters.

Based on the water flow and the drop height, the output of the turbine

is estimated at about 530,000 kilowatt-hours per year; which means that

it can be compared with the consumption of electricity of about 180 families.

For maintenance and control purposes,

a building was erected on top of the turbine. This building also contains

a working space for the Department of Public Works, and a transformer kiosk

Technical data:

| General: |

|

| location |

Weir "De Haandrik", Gramsbergen |

| setting: |

left of the weir |

| drop heigth: |

approx. 2 meters |

| water flow: |

nominal 7 m3/s |

| output: |

530.000 kWh/year |

|

|

| Generator

data |

|

| manufacture. type: |

Stanford SC 344 B synchronous |

| power: |

165 kVA |

| voltage: |

380 V |

| frequency: |

50 Hz |

| drive: |

1500 tpm via cardan shaft |

|

|

| Turbine

data |

|

| manufacturer: |

Jansen Venneboer |

| type |

RR 1600 |

| propellor diameter: |

1.6 m |

| work speed: |

150 rpm |

| rotor blades |

4 aluminium bronze |

| gear box |

2-stage |

| shaft power |

110 kW |

| weight: |

17,000 kg |

|

|

|

|

Source: leaflet Ijsselmij (March

1988)

Generated power

kWh

|

|

Expected

|

1988

|

1989

|

1990

|

1991

|

1992

|

|

Total

|

544,000

|

298,140

|

264,450

|

235,651

|

149,907

|

118,700

|

Economic data

Initial investment (1988) Fl 1,440,735

Automatic trash rack (1990) Fl 90,248

Expected maintenance Fl 10,000/year

|

year

|

operation costs

|

income

|

| |

(guilders)

|

(guilders)

|

|

1988

|

29,000

|

14,000

|

|

1989

|

17,000

|

12,000

|

|

1990

|

19,000

|

18,000

|

|

1991

|

12,000

|

7,000

|

(source:http://194.178.172.86/register/datare/ccr01618.htm)

|